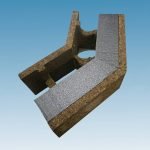

Green Cast Block

A revolutionary method for building frame structures. An insulated block mold for casting walls on-site. Savings in time, cost and energy.

Leaving the traditional casting method behind

Green Cast blocks are molding blocks for casting concrete which cut the building time for frame structures by 50%.

In a one-time pour of concrete, you get: the frame, insulation, and internal and external walls ready for finishing work.

In practice, this construction method, which meets European and Israeli standards, has existed for decades and has met increasing demand in many countries. The concrete mold is used to build internal and external walls, including load-bearing walls, in low-rise and high-rise construction, and in private and public construction.

The mold blocks

The molds are made of a mixture of recycled wood, cement and minerals and meet the dedicated European and Israeli Standard 2263.

The molds provide tremendous savings in heating/cooling energy and have an R = 2.94 maximal degree of thermal resistance.

The molds are lightweight, weighing about 10 kilograms per block, and thus contribute to rapid and precise construction.

Rapid and lightweight construction saves on professional manpower

A first, leveled row of molds/blocks is set in place. The following rows are quickly set without any bonding material. The horizontal and vertical reinforced iron rods are put in place in accordance with the building engineer’s instructions. After six rows are laid, concrete is poured at the same time for all six rows, for the entire circumference of the structure.

The various systems are incorporated as the frame is built. Instead of using traditional chiseling, slits in the block can be made with a wood saw in order to add piping and boxes. The walls are straight and ready for finishing. Cladding products such as plaster, drywall, dry or wet hanging stone, aluminum, etc. can be added. The mold blocks easily adhere to finishing materials.

Characteristics and advantages of molding blocks and the construction method

Use of GreenCast Block has a long list of advantages:

- Affordable building method – use of the blocks has the best cost-benefit ratio in the market. With no need for traditional casting materials, their transport, construction and dismantling, it saves 50% of the time of traditional construction and saves 50% on manpower. There is additional savings on preparing the walls for finishing.

- Thermal insulation – the blocks provide excellent thermal insulation which saves on heating and cooling costs.

- Acoustic insulation – as they are made of wood, the molds provide high acoustic insulation.

- Levels of insulation – there is a selection of molds with different levels of thermal and acoustic insulation to precisely meet required needs.

- Thermal mass – the composition of the mold contributes to the general thermal mass of the wall. The main insulation is on the external side of the wall and does not interfere/cancel out the main thermal mass of the wall (concrete).

- Durability – the molds withstand fire, meeting the Israeli Level 5 standard for combustibility. The molds undergo mineralization and thus exhibit a high level of water resistance and do not swell or disintegrate. The blocks also have high resistance to microorganisms and insects.

- Withstands earthquakes and explosions.

- Molds are lightweight – each mold block weighs about 10 kgs and is thus lightweight building material that is easy to carry, transport and build with – characteristics that aid in more precise and rapid construction.

- Ecological/green – the molds are made of natural materials. Construction processes using molds significantly reduce the amounts of waste and contribute to maintaining a clean and orderly construction site. Ecological construction requires fewer raw material resources such as planks, iron wires, conveyors, wooden boards, etc.